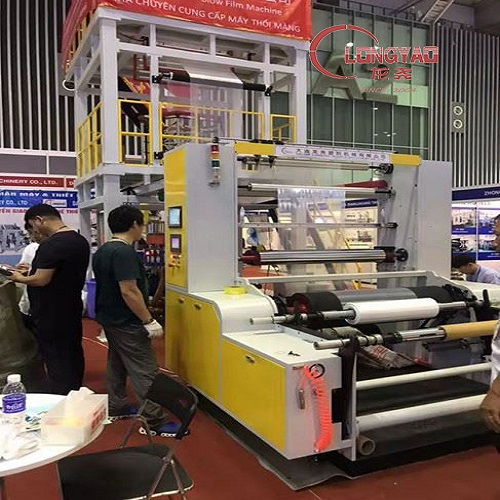

ABA Three Layer Co-extrusion Blown Film Machine

Features

The ABA three-layer co-extrusion blown film machine is a type of machine used to produce plastic films with three layers of different materials. Here are some of the features of this machine:

1. Three-Layer Extrusion: The ABA co-extrusion blown film machine has the ability to extrude three layers of plastic materials simultaneously, resulting in a film with three different layers.

2. Versatility: The machine can be used to produce a wide range of plastic films, including packaging films, agricultural films, and industrial films.

3. High-Quality Output: The three-layer structure of the film produced by this machine results in a high-quality output with excellent mechanical and physical properties, such as strength, tear resistance, and flexibility.

4. Efficient Operation: The ABA co-extrusion blown film machine is designed for efficient operation, with high production capacity and minimal waste.

Product Description

The ABA three-layer co-extrusion blown film machine is a type of film blowing machine that is widely used for producing multilayer plastic films with unique properties. There are several reasons why the ABA film blowing machine is preferred over other types of film blowing machines:

1.Improved film properties: The ABA film blowing machine produces a three-layer film with a unique structure. The outer layers (A) are made of a different material than the inner layer (B), resulting in films with improved mechanical properties such as puncture resistance, tear resistance, and impact strength. The middle layer (B) can also be used as a barrier layer, providing resistance to gas, moisture, and other environmental factors.

2. Cost-effective: The ABA film blowing machine is a cost-effective solution for producing multilayer films with unique properties. By using different materials for the outer and inner layers, manufacturers can achieve the desired properties without having to use expensive materials.

Wide range of applications: The ABA film blowing machine can be used to produce films for a wide range of applications, including packaging, agriculture, construction, and other industrial applications. The unique properties of ABA films make them suitable for various applications, such as heavy-duty bags, agricultural films, and industrial packaging films.

3. Energy-efficient: The ABA film blowing machine is designed to be energy-efficient, which helps to reduce production costs and minimize the impact on the environment.

In summary, the ABA three-layer co-extrusion blown film machine is a popular choice for producing multilayer films with unique properties. Its cost-effectiveness, wide range of applications, and energy efficiency make it a preferred choice for manufacturers in various industries.