ABA Co-Extrusion Plastic Bag Film Blowing Machine

Features

1. plastic bags produced by ABA Co-Extrusion Plastic Bag Film Blowing Machine are a common item in our daily life.

2. industrial Plastic Bag Film Blowing Machine are widely used in the manufacturing of plastic bags for packaging, shopping, and other purposes.

3. Plastic bags produced by film blowing machines are commonly made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE) materials.

4. Plastic bags produced by 3 layer co-extrusion film blowing machine are lightweight, flexible, and durable, making them a popular choice for a wide range of applications.

5. They are used for grocery shopping, storage, transport of goods, and many other purposes.

6. Of course, we are now starting to use degraded raw material particles to produce fully biodegradable shopping bags to meet our daily needs.

Product Detail

Product Description

plastic packaging film blowing machine is a type of machinery used to produce plastic films that are commonly used in various types of packaging applications, such as bags, pouches, and wrapping materials. Here are some key features and components of a typical plastic packaging film blowing machine:

Extruder: This is the core component of the machine, where the plastic material is melted and formed into a molten state. The extruder consists of a screw and barrel that work together to melt and mix the plastic resins.

Die Head: The molten plastic material from the extruder is passed through the die head, which shapes the plastic into a thin tube.

Air Ring: The air ring is positioned around the die head and supplies cool air to the hot plastic tube, allowing it to cool and solidify.

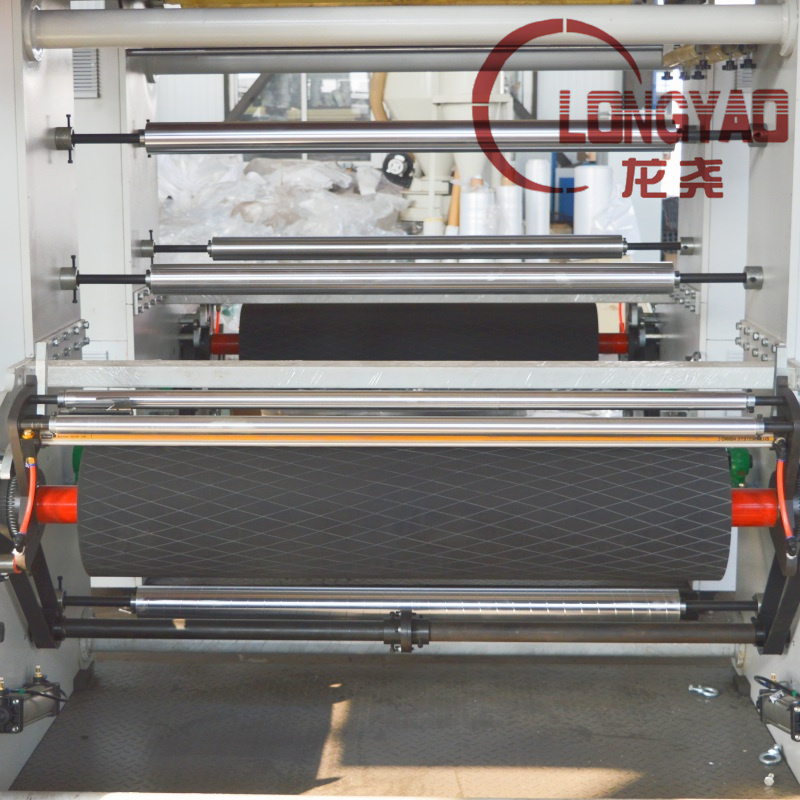

Take-up Unit: The take-up unit consists of rollers that pull the plastic tube out of the die head and wind it onto a roll.

Control System: The machine is controlled by a computerized system that monitors and adjusts the temperature, pressure, speed, and other operating parameters to ensure that the plastic film is produced to the required specifications.

Materials: Plastic packaging film blowing machines can use a variety of plastic materials, including polyethylene (PE), depending on the specific requirements of the application.

Overall, plastic packaging film blowing machines are an important part of the plastic packaging industry, allowing for the production of high-quality and cost-effective packaging materials that are widely used in various industries.