3 Layer Co-extrusion LDPE Shrink Film Blowing Machine

Features

1.This set of 3 Layer Co-extrusion LDPE Shrink Film Blowing Machine adopts LDPE raw material particles which are highly resistant to impact, moisture and chemicals.

2.Universally applicable to LDPE products (e.g. bottles, containers, lids, caps, etc.)

3.Film blowing machine equipment can use 360-degree rotation of the machine head or Oscillating rotating system.

Specification

ABC | MODEL | SJM-Z45X55X45-1200MM | SJM-Z55X65X55-1600MM |

BASIC PARAMETER | Suitable materials | HDPE,LLDPE,Caco3 | |

Film width | 600mm-1100mm | 800mm-1500mm | |

Film thickness | 0.02-0.10mm | ||

Max output | 70-100kg/h | 90-130kg/h | |

Extruder | Screw diameter | Φ45;Φ55;Φ45 | Φ55;Φ65;Φ55 |

Barrel outside diameter | Φ120x3 | Φ120;Φ120;Φ150 | |

L/D | 30:1/32:1 | ||

Main motor power | 18.5KW X2;30KW | 37KW X2;45KW | |

Gear box type | 146X2;180X1 | 180X2;225X1 | |

Die head diameter | Φ100mm

| Φ160mm

| |

Air ring blower | 7.5KW | 15KW | |

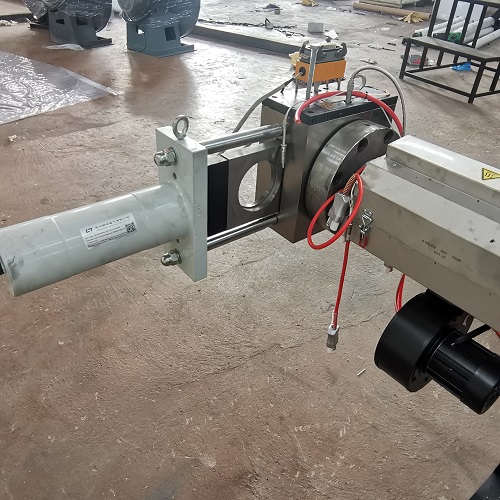

Filter type | Standard screw control /Hydraulic filter screen changer | ||

Take up unit | Roller width | 1200mm | 1600mm |

Take-up speed | 5-100m/min | 5-100m/min | |

Take-up motor | 1.5kw | 2.2kw | |

Rotary type | Horizontal type/oscillating rotating | Horizontal type/oscillating rotating | |

EPC system | Ultrasonic and photoelectric type | ||

Winding unit | Winder type | automatic back to back friction winder /Manual back to back friction winder | |

Automatic tension system | Tension sensor | ||

Winding motor | 1.5kw | 2.2kw | |

Winding speed | 5-100m/min | 5-100m/min | |

Control unit | Electrical part | ABB/Schneider/Siemens | |

inverter | ABB/AILAND/EURA/Yaskawa/Inovance/Slanvert/Delta (according to customer requirements) | ||

Optional | EPC system / Oscillating rotating system / IBC system /automatic winder etc. | ||

Product Detail

Product Description

The operation process of 3 Layer Co-extrusion LDPE Shrink Film Blowing Machine is to add dry polyethylene particles into the lower hopper, and enter the screw from the hopper by the weight of the particles themselves. Facing the plastic, a thrust perpendicular to the beveled surface is generated, and the plastic particles are pushed forward. During the pushing process, due to the friction between the plastic and the screw, the plastic and the barrel, and the collision friction between the particles, and also due to the external heating of the barrel and gradually dissolve. The molten plastic is filtered by the head of the film blowing machine to remove impurities and comes out of the die mouth, cooled by the wind ring, blown through the herringbone plate, traction roller, and coiled to roll the finished film into a cylinder.